Предназначены для оконцевания опрессовкой медных кабелей и проводов. Материал изготовления электротехническая медь марки М2. Покрытие: без покрытия (климатическое исполнение: «УХЛЗ»). Рабочее напряжение: до 35 кВ

Медные кабельные наконечники изготавливаются в соответствии с требованиями ГОСТ 7386-80.

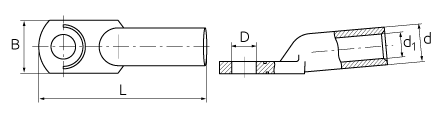

| Наименование | Сечение (мм²) | Винт | Размеры (мм) | |||||

|---|---|---|---|---|---|---|---|---|

| D | B | L | d | d1 | ||||

|

ТМ 2.5–4–2.6 |

2,5 |

2,5 |

M 4 |

4,3 |

8,0 |

28,0 |

5,0 |

2,6 |

|

ТМ 2.5–5–2.6 |

2,5 |

2,5 |

M 5 |

5,3 |

10,0 |

28,0 |

5,0 |

2,6 |

|

ТМ 2.5–6–2.6 |

2,5 |

2,5 |

M 6 |

6,4 |

12,0 |

30,0 |

5,0 |

2,6 |

|

ТМ 4–5–3 |

4 |

4 |

M 5 |

5,3 |

10,0 |

32,0 |

5,0 |

3,0 |

|

ТМ 4–6–3 |

4 |

4 |

M 6 |

6,4 |

12,0 |

32,0 |

5,0 |

3,0 |

|

ТМ 6–5–4 |

6 |

6 |

M 5 |

5,3 |

10,0 |

32,0 |

6,0 |

4,0 |

|

ТМ 6–6–4 |

6 |

6 |

M 6 |

6,4 |

12,0 |

32,0 |

6,0 |

4,0 |

|

ТМ 10–5–5 |

10 |

10 |

М 5 |

5,3 |

11,0 |

40,0 |

8,0 |

5,0 |

|

ТМ 10–6–5 |

10 |

10 |

М 6 |

6,4 |

14,0 |

40,0 |

8,0 |

5,0 |

|

ТМ 10–8–5 |

10 |

10 |

М 8 |

8,4 |

16,0 |

40,0 |

8,0 |

5,0 |

|

ТМ 16–6–6 |

16 |

16 |

М 6 |

6,4 |

14,0 |

40,0 |

9,0 |

6,0 |

|

ТМ 16–8–6 |

16 |

16 |

М 8 |

8,4 |

16,0 |

40,0 |

9,0 |

6,0 |

|

ТМ 25–6–7 |

25 |

25 |

М 6 |

6,4 |

15,0 |

45,0 |

10,0 |

7,0 |

|

ТМ 25–8–7 |

25 |

25 |

М 8 |

8,4 |

16,0 |

45,0 |

10,0 |

7,0 |

|

ТМ 35–8–9 |

35 |

35 |

М 8 |

8,4 |

18,0 |

60,0 |

12,0 |

9,0 |

|

ТМ 35–10–9 |

35 |

35 |

М 10 |

10,5 |

20,0 |

60,0 |

12,0 |

9,0 |

|

ТМ 35–12–9 |

35 |

35 |

М 12 |

13,0 |

22,0 |

60,0 |

12,0 |

9,0 |

|

ТМ 50–8–11 |

70 |

50 |

М 8 |

8,4 |

20,0 |

63,0 |

14,0 |

11,0 |

|

ТМ 50–10–11 |

70 |

50 |

М 10 |

10,5 |

22,0 |

63,0 |

14,0 |

11,0 |

|

ТМ 50–12–11 |

70 |

50 |

М 12 |

13,0 |

24,0 |

63,0 |

14,0 |

11,0 |

|

ТМ 70–10–13 |

95 |

70 |

М 10 |

10,5 |

24,0 |

65,0 |

16,0 |

13,0 |

|

ТМ 70–12–13 |

95 |

70 |

М 12 |

13,0 |

24,0 |

65,0 |

16,0 |

13,0 |

|

ТМ 95–10–15 |

120 |

95 |

М 10 |

10,5 |

28,0 |

75,0 |

19,0 |

15,0 |

|

ТМ 95–12–15 |

120 |

95 |

М 12 |

13,0 |

28,0 |

75,0 |

19,0 |

15,0 |

|

ТМ 120–12–17 |

150 |

120 |

М 12 |

13,0 |

34,0 |

81,0 |

22,0 |

17,0 |

|

ТМ 120–16–17 |

150 |

120 |

М 16 |

17,0 |

34,0 |

81,0 |

22,0 |

17,0 |

|

ТМ 150–12–19 |

185 |

150 |

М 12 |

13,0 |

36,0 |

90,0 |

25,0 |

19,0 |

|

ТМ 150–16–19 |

185 |

150 |

М 16 |

17,0 |

36,0 |

90,0 |

25,0 |

19,0 |

|

ТМ 185–16–21 |

240 |

185 |

М 16 |

17,0 |

40,0 |

95,0 |

27,0 |

21,0 |

|

ТМ 185–20–21 |

240 |

185 |

М 20 |

21,0 |

40,0 |

95,0 |

27,0 |

21,0 |

|

ТМ 240–16–24 |

300 |

240 |

М 16 |

17,0 |

48,0 |

105,0 |

32,0 |

24,0 |

|

ТМ 240–20–24 |

300 |

240 |

М 20 |

21,0 |

48,0 |

105,0 |

32,0 |

24,0 |

|

ТМ 300-16-27 |

400 |

300 |

М 16 |

17,0 |

50,0 |

105,0 |

34,0 |

27,0 |

|

ТМ 300-20-27 |

400 |

300 |

М 20 |

21,0 |

50,0 |

105,0 |

34,0 |

27,0 |